bubble breakthrough

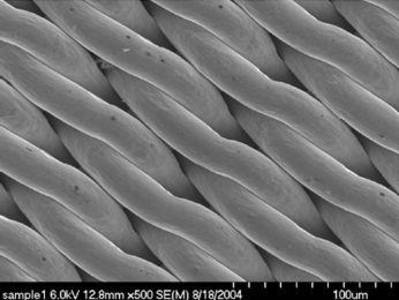

On earth and in space alike, the quality of combustion depends on the quality of fuel. Bubbles that can enter the fuel for example by sloshing would significantly diminish this quality and must therefore be avoided. In space applications this is achieved by the use of filter screens as shown in Fig. 1.

Such screens are woven with fine stainless steel wire which makes them flexible, highly resilient towards mechanical and thermal stresses and lightweight. Besides, the fuel 'sticks' to the steel weave due to its high surface energy and thus perfectly wets it. As a consequence, the fuel prevents air bubbles from passing through the weave - at least up to a critical pressure difference, the so-called bubble point. If the bubble point is reached or even trespassed, bubble breakthrough occurs (Fig. 2).

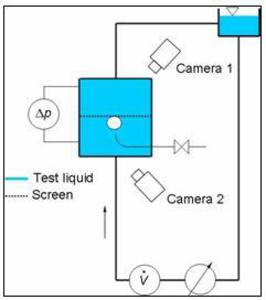

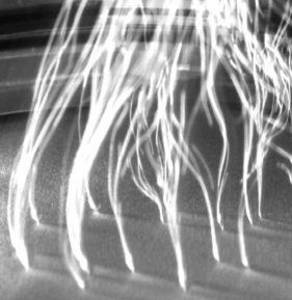

Our experimental arrangement allows for upward and downward fluid flow through the weave. In our upward flow experiments we measure the pressure loss over the weave as a test fluid passes through at variable flow rate. Air bubbles that are inducted into the flow become trapped at the screen and coalesce to one, see Fig. 3. Its presence reduces both the cross section for the flow and therefore the critical flow rate at which the bubble point occurs.

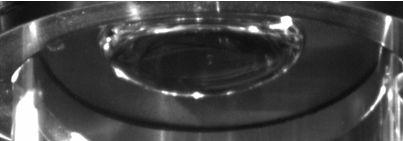

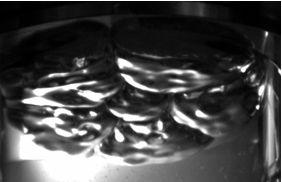

As the bubble grows in size (caused by further small bubbles that coalesce) the cross section is decreased until it is eventually blocked. We are interested in the static bubble point of the weave (no flow) which is a characteristic feature of filter weaves as well as its variable dynamic bubble point (flow present). In our downward flow experiments we observe the behaviour of a trapped bubble below the weave which now can no longer block the flow. Under these conditions the bubble can behave very interesting, as the beauty of some observed patterns illustrates, see Fig. 4.

"

"